Best RF Shield Boxes for 5G, IoT, and Wi-Fi 6 Testing in 2025

The quick development of wireless technologies demands precision in electromagnetic interference (EMI) testing. RF shield boxes have become useful tools for engineers developing 5G devices, IoT solutions, and Wi-Fi 6 equipment. These specialized enclosures provide controlled testing environments that offer regulatory compliance and optimal device performance.

Modern RF testing requires isolation from external interference while maintaining precise control over test conditions. Whether you’re validating 5G mm Wave performance or testing IoT device connectivity, the right RF shielded chamber can make the difference between passing certification and costly redesigns.

What Makes RF Shield Boxes Highly Important for Modern Wireless Testing?

RF shield boxes create isolation chamber environments that block external electromagnetic signals while containing device emissions. This isolation is critical for accurate testing of wireless devices operating in increasingly crowded spectrum environments.

Today’s wireless testing challenges include:

- 5G mmWave sensitivity requiring ultra-clean RF environments

- IoT device growth creating complex interference scenarios

- Wi-Fi 6 multi-band testing across 2.4GHz, 5GHz, and 6GHz bands

- Automotive detection testing for ADAS and autonomous vehicle systems

RFIsolation specializes in providing professional EMI/RFI testing solutions that manage these evolving requirements with precision-engineered enclosures.

Why Do 5G Devices Require Specialized RF Testing Equipment?

5G technology operates across multiple frequency bands, from sub-6GHz to mmWave frequencies above 24GHz. Each band presents unique testing challenges that demand sophisticated RF isolation capabilities.

Key 5G testing requirements include:

- Massive MIMO antenna testing requiring large test volumes

- beam-formation validation needing precise angular measurements

- mmWave reflection testing sensitive to environmental factors

- Network slicing verification across multiple frequency bands

Traditional test setups often fail to provide the isolation needed for reliable 5G measurements. Modern RF test enclosures must accommodate multiple antennas while maintaining excellent shielding effectiveness across broad frequency ranges.

How Do IoT Devices Benefit from Controlled RF Testing Environments?

IoT devices operate in multiple environments with variable interference levels. RF testing for IoT devices must reflect real-world conditions while providing repeatable measurements for certification compliance.

Critical IoT testing scenarios:

- Low-power device sensitivity requiring minimal noise floors

- Coexistence testing between multiple wireless protocols

- Range and connectivity validation under controlled conditions

- Battery life optimization through efficient RF design

What RF Shielding Requirements Does Wi-Fi 6 Testing Demand?

Wi-Fi 6 introduces advanced features like OFDMA, BSS coloring, and extended frequency ranges that require sophisticated testing approaches. Shield boxes for wireless testing must accommodate these enhanced capabilities.

Wi-Fi 6 testing considerations:

- 6GHz band validation requiring broadband shielding effectiveness

- Multi-user MIMO testing with complex antenna settings

- Power efficiency measurements across varying traffic loads

- Coexistence testing with existing Wi-Fi and cellular networks

The extended frequency range of Wi-Fi 6E (up to 7.125GHz) demands RF shielding cabinets with consistent performance across these broader spectrum ranges.

How to Choose the Right RF Shield Box for Your Testing Needs?

Selecting appropriate RF testing equipment requires careful consideration of frequency ranges, device sizes, and testing methodologies. The right choice impacts both test accuracy and development timelines.

Key selection criteria:

Frequency Coverage:

- Maintain shielding effectiveness across your target bands

- Consider future frequency expansions

- Verify performance at band edges and harmonics

Physical Dimensions:

- Accommodate device under test plus cables

- Allow for antenna positioning flexibility

- Consider future device size growth

Shielding Performance:

- Minimum 80dB isolation for most applications

- Higher isolation (100dB+) for sensitive measurements

- Consistent performance across frequency range

Connectivity Options:

- Filtered power connections

- RF feedthrough options

- Data connectivity for automated testing

What Types of RF Shield Boxes Are Available for Different Applications?

Modern testing requirements demand different EMI shield box setups. Understanding available options helps match solutions to specific testing needs.

1. Desktop RF Shield Boxes

Compact solutions ideal for component-level testing and R&D applications. These units offer excellent portability while maintaining professional shielding performance.

2. Rack Mount RF Shield Boxes

Rack mount RF boxes integrate perfectly into existing test equipment setups. They provide standardized form factors while offering superior shielding for production testing environments.

3. Custom RF Test Chambers

Large-scale RF shielded chambers accommodate complete system testing, including automotive components and medical devices requiring advanced EMI evaluation.

4. Portable RF Test Enclosures

Field-deployable solutions enabling on-site testing and validation. These units balance portability with performance for different testing scenarios.

RF Shield Box Comparison: Key Features and Applications

| Type | Frequency Range | Typical Size | Best Applications | Shielding Performance |

|---|---|---|---|---|

| Desktop RF Box | DC-40GHz | 30x30x20cm | Component testing, R&D | 80-100dB |

| Rack Mount Box | DC-50GHz | 19″ rack width | Production testing | 90-110dB |

| Test Chamber | DC-40GHz | 1m³ and larger | System-level testing | 100-120dB |

| Portable Enclosure | DC-26GHz | Variable | Field testing | 70-90dB |

What Industries Benefit Most from Advanced RF Testing Solutions?

Electromagnetic interference shielding serves multiple industries, each with specific requirements and regulatory compliance needs.

Telecommunications Industry: 5G infrastructure and device manufacturers require advanced RF compliance testing to maintain network compatibility and performance optimization.

Automotive Sector: Electric and autonomous vehicles incorporate numerous wireless systems, requiring EMI shielding for automotive applications. Radar, V2X communication, and information management systems all demand rigorous testing.

Medical Device Manufacturing: EMI shielding for medical devices guarantees patient safety and device reliability. Wireless patient monitoring and implantable devices require specific RF testing protocols.

Defense and Aerospace: Military and aerospace applications demand the highest levels of RF signal isolation to prevent interference with critical systems and maintain operational security.

How Do Modern RF Shield Boxes Maintain Testing Accuracy?

New RF test racks incorporate advanced design features that enhance measurement accuracy and repeatability. These improvements directly impact product development success rates.

Advanced design features:

- Modular construction enabling custom configurations

- Integrated filtered connections reducing installation complexity

- Automated door systems provide consistent sealing

- Environmental controls maintaining stable test conditions

Quality certifications like CE Certified RF Enclosures and ISO 9001:2015 EMI Products provide assurance of consistent manufacturing standards and performance reliability.

What Future Trends Are Shaping RF Testing Requirements?

Emerging wireless technologies continue expanding RF testing complexity. RF testing for electronics must grow to match next-generation requirements.

Key technology trends:

- 6G research pushing frequency ranges beyond 100GHz

- Satellite system growth, increasing interference potential

- Edge computing integration requiring localized testing capabilities

- High-frequency communication demanding ultra-low noise environments

RFIsolation stays ahead of these trends by continuously developing custom EMI/RF testing solutions that satisfy emerging technology requirements.

How to Implement Effective RF Testing Procedures?

Successful RF testing requires more than just quality equipment. Proper procedures offer reliable results and regulatory compliance.

Best practices for RF testing:

Environment Preparation:

- Verify ambient RF levels before testing

- Calibrate equipment regularly

- Document environmental conditions

Test Procedure Development:

- Follow industry standards (FCC, CE, IC)

- Implement repeatable measurement sequences

- Maintain detailed test records

Data Analysis:

- Compare results against regulatory limits

- Identify potential interference sources

- Document compliance margins

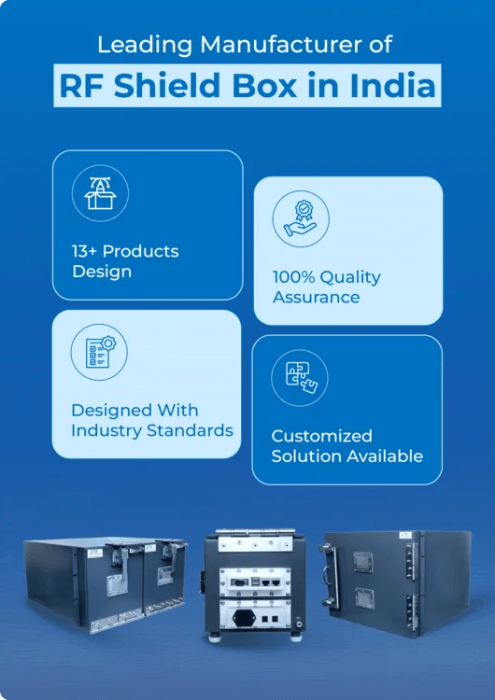

Choose RFIsolation for Your RF Testing Success

Selecting the right RF shield box greatly impacts your product development timeline and regulatory compliance success. RFIsolation provides detailed EMI/RFI testing solutions designed for modern wireless technology requirements.

Our product range includes RF desktop shield boxes, rack mount RF boxes, and custom RF test chambers engineered to satisfy unique industry needs. From 5G device validation to IoT connectivity testing, we provide the precision and reliability your projects demand.

Ready to grow your RF testing capabilities? Contact RFIsolation today to discuss your specific requirements and learn how our RF testing equipment can improve your product development while maintaining regulatory compliance.

Visit RFIsolation.in to explore our complete range of RF shielding solutions and request a consultation with our technical experts.

Most 5G testing requires minimum 80dB shielding effectiveness, with mmWave applications often needing 100dB or higher isolation to provide accurate measurements.

Yes, larger RF test enclosures can accommodate multiple devices for coexistence testing, though proper spacing and isolation between devices is very important for accurate results.

Regular door seal inspection, connector cleaning, and periodic shielding effectiveness verification guarantee continued performance. Replace worn seals promptly to maintain isolation.

Look for CE certification, ISO 9001:2015 quality management compliance, and commitment to relevant EMC testing standards specific to your industry requirements.

Yes, custom EMI/RF testing solutions can manage specific dimensional, frequency, or connectivity requirements that standard products cannot accommodate effectively.