RF Shielded Racks What They Are, How They Work & Complete Buyer Guide

RF shielded racks are specialized enclosures designed to isolate radio frequency (RF) testing equipment from external electromagnetic interference (EMI), ensuring accurate measurements and reliable test results. These racks create a controlled RF environment essential for testing wireless devices, 5G/6G equipment, and conducting pre-compliance EMC testing.

When you’re developing wireless devices or conducting RF measurements, external interference can turn your test data into guesswork. That’s where RF shielded racks become mission-critical infrastructure for test labs, R&D facilities, and manufacturing quality control environments.

At RF Isolation, we’ve helped hundreds of test engineers achieve measurement accuracy by implementing the right RF isolation solutions. This guide explains everything you need to know about RF shielded racks – from how they work to choosing the perfect system for your specific testing requirements.

What Is RF Shielded Racks?

An RF shielded rack is a specialized enclosure that combines standard equipment rack functionality with electromagnetic shielding capabilities. Similar to regular server racks, these units feature continuous metallic shielding that blocks external RF signals from entering and prevents internal test signals from escaping.

Think of it as a faraday cage designed specifically for rack-mounted test equipment. The shielding effectiveness typically ranges from 60 dB to over 100 dB across various frequency ranges, depending on the design and application requirements.

RF shielded rack cabinets serve as the foundation for creating isolated test environments without the space and cost requirements of full-scale RF chambers. They’re particularly valuable for labs conducting multiple independent tests or facilities with limited floor space.

How Do RF Shielded Racks Work?

The science behind RF isolation racks is straightforward but requires precise engineering execution.

The Shielding Mechanism

RF shielded enclosure racks work by creating a continuous conductive barrier around your test equipment. This barrier operates on two fundamental electromagnetic principles:

Reflection: When RF waves hit the conductive shielding material, most of the energy reflects, preventing it from penetrating the enclosure. The effectiveness depends on the shield material’s conductivity and thickness.Absorption: Any RF energy that doesn’t reflect gets absorbed by the shielding material and converts to minimal heat. Multi-layer shielding designs maximize this absorption across broader frequency ranges.

Critical Design Elements

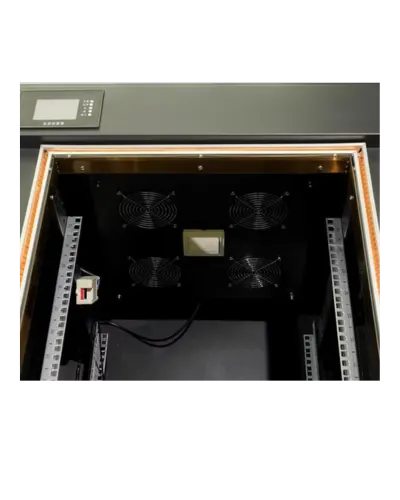

Every effective rack mount RF shielding system includes these essential components:

- Continuous metallic enclosure with no gaps or seams that could leak RF signals

- RF gaskets and fingerstock at all panel joints and door edges to maintain electrical continuity

- Filtered power entry to prevent interference from entering through power lines

- Shielded cable penetrations with honeycomb or waveguide filters for necessary connections

- Proper grounding system to dissipate unwanted RF energy safely

The key is maintaining shield integrity across all access points while still allowing practical equipment operation.

Why Your Test Lab Needs RF Shielded Racks

Eliminate RF Interference from Your Testing

Modern test environments face unprecedented RF noise. Wi-Fi networks, cellular signals, Bluetooth devices, and nearby equipment all create interference that corrupts your measurements. An RF test rack system isolates your device under test (DUT) from this electromagnetic chaos. You get repeatable, reliable results regardless of what’s happening in the surrounding environment.Achieve Regulatory Compliance Faster

When conducting pre-compliance EMC/EMI testing, ambient interference makes it impossible to accurately assess your product’s emissions or susceptibility. Shielded racks for RF testing create the controlled environment necessary for meaningful pre-compliance measurements. This significantly reduces failures during formal certification testing – saving both time and money.Protect Sensitive Measurements

Testing 5G and 6G devices demands extreme measurement accuracy. Signal levels can be incredibly low, making them vulnerable to noise interference. A properly configured EMI shielded rack provides the quiet RF environment essential for characterizing these advanced wireless technologies. You can measure what your device is actually doing rather than measuring environmental noise.Enable Concurrent Testing

Full RF chambers are expensive and can only test one device at a time. RF shielded rack cabinets allow multiple simultaneous tests in the same lab space without cross-contamination between test stations.Key Features to Look for in an RF Shielded Rack

Shielding Effectiveness Across Your Operating Frequencies

Don’t assume all shielding is equal. Verify the shielding effectiveness specification that matches your actual test frequencies. A rack with 80 dB shielding at 1 GHz might only provide 60 dB at 6 GHz.

Request shielding effectiveness of data across your entire frequency range of interest, especially if you’re testing 5G/6G devices operating at millimeter-wave frequencies.

Usability and Access

The best shielding means nothing if you can’t efficiently operate your equipment. Look for:

- Quick-access doors with reliable RF gasket compression

- Cable pass-through panels with appropriate filtering

- Internal lighting that doesn’t compromise shielding

- Ventilation systems that maintain shielding integrity while managing heat

Build Quality and Longevity

- Effective hinge mechanisms

- Commercial-grade RF gaskets

- Corrosion-resistant materials

- Comprehensive warranty coverage

Integration Capabilities

Your RF rack enclosure should integrate properly with your existing test infrastructure:- Standard 19-inch rack mounting for conventional equipment

- Compatible with existing grounding systems

- Flexible power entry options

- Modular design for future expansion

Applications: Where RF Shielded Racks Make the Difference

Wireless Device Development

From smartphones to IoT sensors, every wireless device needs rigorous RF testing. Shielded racks create the controlled environment necessary for accurate antenna characterization, transmitter measurements, and receiver sensitivity testing.

Automotive Testing

Modern vehicles contain dozens of wireless systems. RF test rack systems enable automotive engineers to test everything from key fobs to V2X communication systems without interference from the lab’s other active systems.

Medical Device Development

Wireless medical devices must meet strict performance and safety standards. RF isolation racks provide the measurement accuracy required for regulatory submissions while enabling faster development cycles.

Aerospace and Defense

Military and aerospace applications demand the highest reliability standards. RF shielded enclosure racks support classified testing environments and ensure measurement accuracy for mission-critical systems.

How to Choose the Right RF Shielded Rack for Your Lab

Step 1: Define Your Frequency Requirements

Start by identifying your test frequency ranges. Testing sub-6 GHz 5G requires different shielding specifications than testing 28 GHz millimeter-wave systems.

Higher frequencies demand tighter construction tolerances and more sophisticated gasket designs to maintain shielding effectiveness.

Step 2: Calculate Your Equipment Space Needs

List all equipment that needs to live inside the shielded environment. Remember to account for:

- Test instruments (spectrum analyzers, signal generators, etc.)

- Device under test (DUT) positioning

- Cabling and connection space

- Future expansion capacity

Add 20-30% extra capacity to avoid outgrowing your rack too quickly.

Step 3: Evaluate Access Requirements

How frequently will you change test setups? Labs with constant device changes need easy-access designs with quick-release doors. Long-term installations can optimize for maximum shielding over access convenience.

Step 4: Consider Environmental Factors

Equipment generates heat. Ensure your shielded server rack for RF testing includes adequate ventilation that doesn’t compromise shielding. Some designs use honeycomb waveguide ventilation that allows airflow while blocking RF signals.

Step 5: Plan Your Integration

How will the rack integrate with your existing lab infrastructure? Consider:

- Available floor space and layout

- Power requirements and filtering needs

- Grounding and bonding to facility ground

- Cable routing and management

- Future reconfiguration flexibility

Step 6: Verify Compliance and Certification

Request third-party shielding effectiveness test reports. Reputable manufacturers provide documented proof of performance across specified frequency ranges.

RF Isolation provides detailed shielding effectiveness documentation with every system, ensuring you know exactly what you’re getting.

Common Mistakes to Avoid When Buying RF Shielded Racks

- Underestimating frequency range requirements: Your rack must shield effectively across all frequencies you’ll test, not just today’s primary application.

- Ignoring usability: The most affordable rack becomes expensive if it slows down your testing workflow by 30%.

- Overlooking ventilation: Overheated equipment produces unreliable results. Proper ventilation within shielding constraints is non-negotiable.

- Skipping grounding planning: Improper grounding can completely negate shielding effectiveness. Plan your grounding strategy before installation.

Ready to Upgrade Your RF Test Environment?

Implementing the right RF shielded rack cabinet transforms your measurement accuracy and testing efficiency. Whether you’re building a new test lab or upgrading existing facilities, the right isolation solution eliminates the RF interference that compromises your results.

RF Isolation offers advanced RF shielding solutions customized to your specific testing requirements – from compact desktop shield boxes to full test rack systems designed for 5G and 6G device testing.

Get expert guidance on your RF isolation needs. Our engineering team helps you select the optimal configuration for your testing environment and budget. Contact us today for a consultation and detailed quote.

Frequently Asked Questions

Q: What’s the difference between RF shielded racks and regular server racks?

A: RF shielded racks include continuous electromagnetic shielding (typically 60-100+ dB attenuation) to block external RF interference and contain internal test signals. Regular server racks are simply mechanical enclosures without any RF isolation capabilities.

Q: Can I use an RF shielded rack for EMC pre-compliance testing?

A: Yes. RF shielded racks are excellent for pre-compliance EMC/EMI testing. They provide sufficient isolation for identifying potential compliance issues before formal certification testing, significantly reducing the risk of costly failures during official testing.

Q: How much shielding effectiveness do I need for 5G device testing?

A: For sub-6 GHz 5G testing, target minimum 70-80 dB shielding effectiveness. For millimeter-wave 5G (24 GHz and above), you’ll want 80-100+ dB shielding with specifications verified at your specific test frequencies.

Q: Do RF shielded racks require special installation or facility modifications?

A: Most RF shielded racks require only proper grounding connection to your facility ground system and standard electrical power. Unlike full RF chambers, they typically don’t require structural facility modifications or special HVAC systems.

Q: How long do RF gaskets and shielding components last?

A: Quality RF gaskets typically maintain effectiveness through 10,000+ door cycles when properly maintained. Shielding effectiveness should remain stable for 5-10+ years with normal use. Regular inspection and occasional gasket replacement ensure continued performance.