Essential RF Test Equipment for Aerospace Industry Testing

There is no room for error in the aerospace industry.

Any errors faced due to RFI and EMI in the aerospace industry can lead to malfunctions of aviation systems and more life-threatening risks.

Hence, the aerospace industry demands high security, efficiency, and compatibility with the most stringent compliance requirements for reliability.

To do so, the aerospace industry heavily relies on high-quality RF test equipment designed to test and measure the performance of aviation systems.

Read on to learn more about the role of RF test equipment solutions in the aerospace industry and things to consider when choosing RF equipment for the aerospace industry.

We’ll also discuss avionics testing, testing challenges, and uses of RF testing equipment in that place.

What Is Avionics Testing?

Aviation systems are an integral part of aircraft, and avionics testing is essential to allow these systems to operate safely as expected.

Here, avionics refers to the electronic systems used in aircraft for controlling and monitoring various functions. Avionics systems include navigation, communication, and flight control, which are more vulnerable to RF interference.

Avionics testing plays a crucial role in ensuring reliability, functionality, and safety for these systems for uninterrupted performance.

Moreover, to perform avionics testing, high-quality RF test equipment is required for efficient and accurate testing results. Let’s explore more about RF test equipment below.

What Is RF Test Equipment?

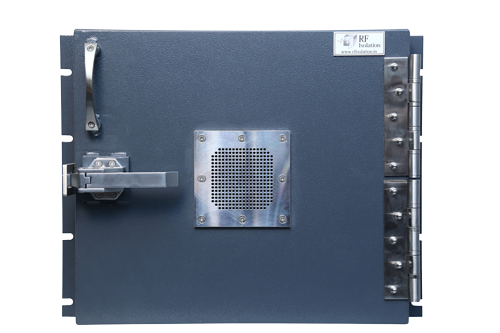

RF test equipment is necessary equipment used in the aerospace industry to protect aviation systems from being disrupted by external electromagnetic signals and radio frequencies.

Essentially, RF testing equipment blocks RF and EM signals from entering the product, which can disrupt electronic systems.

Interference caused by radio frequencies and electromagnetic signals can lead to system malfunctions, communication failures, temporary disturbances, data losses, and, in the case of the aerospace industry, even loss of life.

There are different types of RF test equipment solutions available to protect aviation systems from EM and RF interference. Some of the common ones include:

- RF Standalone Shield Box

- RF Desktop shield box

- Rack Mount RF shield box

- RF Test rack

- RF Chambers

Role Of RF Test Equipment In Aerospace Industry

The electronics systems used in aerospace applications must operate at the highest efficiency level with optimum security. This is where the role of RF equipment comes into play.

The purpose of RF testing equipment solutions in aerospace applications is to block unwanted signals and frequencies from reaching and interfering with the sensitive parts of aviation systems.

Many aviation devices rely on radio frequencies and electromagnetic signals to function; however, interruption from external signals can cause damage and malfunction.

RF testing equipment helps these systems operate as per the application requirements without any concerns or challenges. They prevent all unwanted signals and frequencies that can cause aviation systems to fail or malfunction.

Uses for RF Test Equipment In the Aerospace Industry

Uses for RF equipment in aviation and aerospace industries depend on the unique system and application. Although, the main use of RF testing equipment is to provide protection against various challenges posed by radio frequency interference.

Below are some of the most common applications of RF equipment for the aerospace industry:

1. Preventing Unwanted External Interference

Electromagnetic signals and radio frequencies are everywhere and pose risks to various electronic systems sensitive to such interference.

Even though the majority of radio frequencies are unintentional, they create the same challenges as intentional. RF testing devices help block out this external radio frequency interference for optimal device functioning.

2. Blocking Signals Interference Between Device

Sometimes electromagnetic and radio frequency interference is produced within the device itself. There are many aviation systems that function upon radio frequency signals and are highly sensitive to external radio frequencies as well.

RF test equipment plays an important role in protecting such systems from outside interference and blocking signal interference between device parts.

3. Avoiding Communication Interference

Clear communication in the aerospace industry is highly important. Radiofrequency interruption in communication can make it difficult to pass important information, leading to dangerous problems.

RF testing equipment can help prevent RFI garbling messages or adding unnecessary noises for clean and clear communication.

Importance Of RF Test Equipment Across Industries

Medical Industry

RF test equipment is highly important in accurate testing performance, functionality and efficiency of various medical devices and healthcare instruments.Automotive Sector

RF testing devices in the automotive sector help improve the functionality and operability of vehicles. It is also used for testing and performance analysis of new vehicles, safety compliance testing, and predicting and optimizing vehicle performance.Electronic Industry

The necessity of RF test equipment is high in the electronic industry for performance analysis and validation of various electric and electronic devices, including batteries, semiconductors, etc.5G Technologies

The latest 5G technologies have higher bandwidth requirements, which generates the need for testing and measuring device compatibility and performance with RF testing equipment.Consideration When Choosing RF Test Equipment For Aerospace Industry Testing

➦ Robust Design

Choose RF testing equipment with advanced testing capabilities for proper testing, accurate results, and robust design that can’t be damaged easily.

➦ Easy Usability

The design of devices and controls should be intuitive and not complex for easy device handling and seamless operation.

➦ High Durability

Every part and component of RF testing equipment should be durable enough to withstand various challenges and survive repeated use.

➦ Expandability

The RF testing equipment you choose should not only perform optimally for the current requirements but should also be flexible enough to change over time.

➦ High Test Coverage

RF test solutions should have maximum coverage to block all unwanted signals and frequencies and leave no place for mistakes during device testing.

➦ Compact Design

For an industry with limited space, choose an RF test equipment solution that utilizes minimum space and is portable for easy setup and transportation.

To Conclude

RF Test Equipment in the aerospace industry is highly important and will only become essential over time.

When choosing RF testing equipment, it is vital to choose one strategically built to adhere to the most rigorous quality and security standards of the aerospace industry.

You need a manufacturing partner you can trust blindly for quality and performance. RF Isolation is the most trusted RF test equipment manufacturer in India, helping various industries with high-quality RF enclosures.

We pride ourselves on being the first choice for aerospace applications. Our extensive range of RF test equipment is manufactured to stand up to the harshest conditions.

For product requirements, reach out to us now.